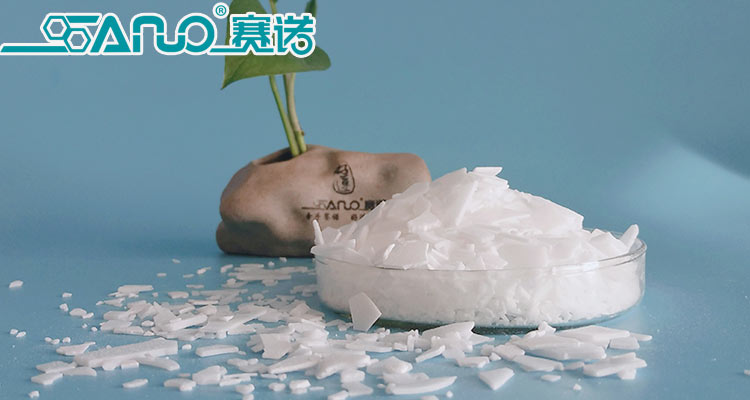

Polyethylene wax is an indispensable and important additive for the preparation of color masterbatches, with its main functions as a dispersant and lubricant. There are several necessary conditions in the selection of polyethylene wax: high thermal stability, appropriate molecular weight, narrow molecular weight distribution, and strong dispersion ability.

In the production of color masterbatches, there is not only good compatibility and flowability, but also moderate viscosity, increased shear force, improved dispersibility, and excellent pigment wetting and dispersion performance. For PE and PP masterbatches with high pigment content, it has a good wetting and dispersing effect and is widely used as a dispersant (diffusion powder) for general masterbatches and blown film masterbatches, improving the coloring power of pigments.

The role of masterbatch in plastic processing:

1. Plastic masterbatch is prepared by adding plastic additives beyond the conventional dosage to the carrier resin, so it can be directly added to plastic products during molding.

2. Filling masterbatch can reduce raw material costs and improve the rigidity, hardness, and wear resistance of plastic products.

3. Lubricating masterbatch can make the produced plastic film easy to open, improve production efficiency, and reduce waste rate.

4. Transparent masterbatch can improve the transparency of products and process products with different transparency to meet the different requirements of users for products.

5. Pearlescent masterbatch can endow plastic products with bright and pleasing colors, improving their packaging value and decorative effect.

6. Color masterbatch can provide satisfactory color effects for plastic products.

7. Anti static masterbatch can reduce the surface resistance and static attenuation half-life of plastic products, in order to achieve the effect of surface dust removal.

Pe wax can be used as a dispersant for color masterbatches of various thermoplastic resins, as well as a lubricating dispersant for filling masterbatches and degrading masterbatches. Polyethylene wax has good compatibility with plastics, good heat resistance, good mixing ability, and is easy to crush, without affecting the performance of end products; It has a wetting, dispersing, and stabilizing effect on the particles of fillers or pigments.

For more details, please consult us! inquiry

Qingdao Sainuo Group. We are manufacturer for PE wax, PP wax, OPE wax, EVA wax, PEMA,EBS,Zinc/Calcium Stearate…. Our products have passed the REACH, ROHS, PAHS, FDA testing.

Sainuo rest assured wax, welcome your inquiry!

E-mail:sales@qdsainuo.com

sales1@qdsainuo.com

sales9@qdsainuo.com

Adress:Biulding No 15,Torch Garden Zhaoshang Wanggu, Torch Road No. 88,Chengyang,Qingdao,China

Post time: Mar-03-2025