News

-

![[pe wax] Common testing methods for powder coatings](//cdnus.globalso.com/sanowax/powder-coating-colours-and-finishes1.jpg)

[pe wax] Common testing methods for powder coatings

1. Appearance recognition method The texture is smooth, fluffy and extremely light, the quality is good; otherwise, the quality is poor. The larger the volume, the better the quality; otherwise, the quality is poor. The longer the storage time, the better the quality; on the contrary, it ...Read more -

![[Polyethylene Wax] Some limitations of color masterbatch](//cdnus.globalso.com/sanowax/微信图片_20190917154756.jpg)

[Polyethylene Wax] Some limitations of color masterbatch

Color masterbatch plays an important color function in the injection molding industry. But there are limitations when using color masterbatch. After all, everything in the world cannot be perfect. Today, Qingdao Sainuo polyethylene wax manufacturer will show you the limitations of color masterb...Read more -

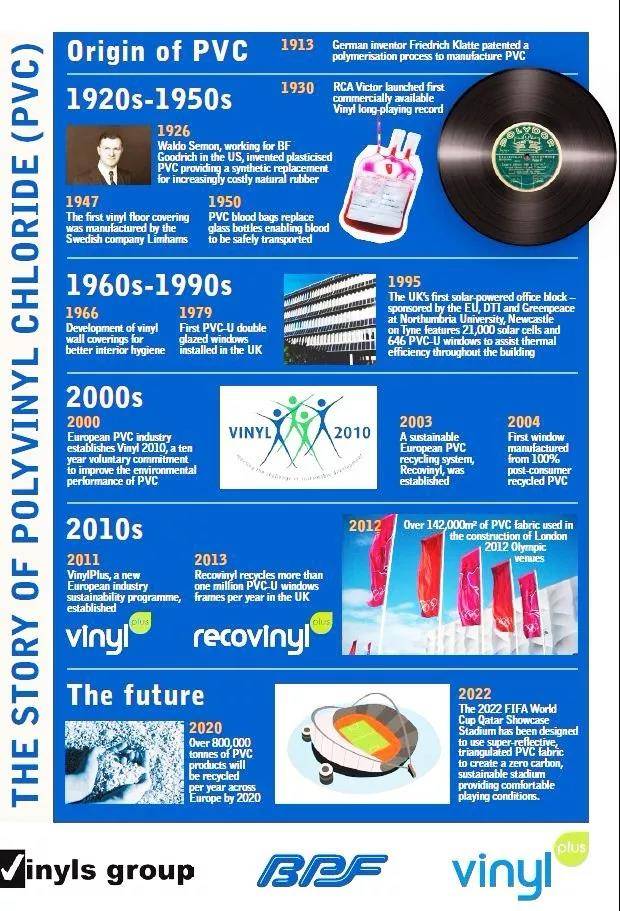

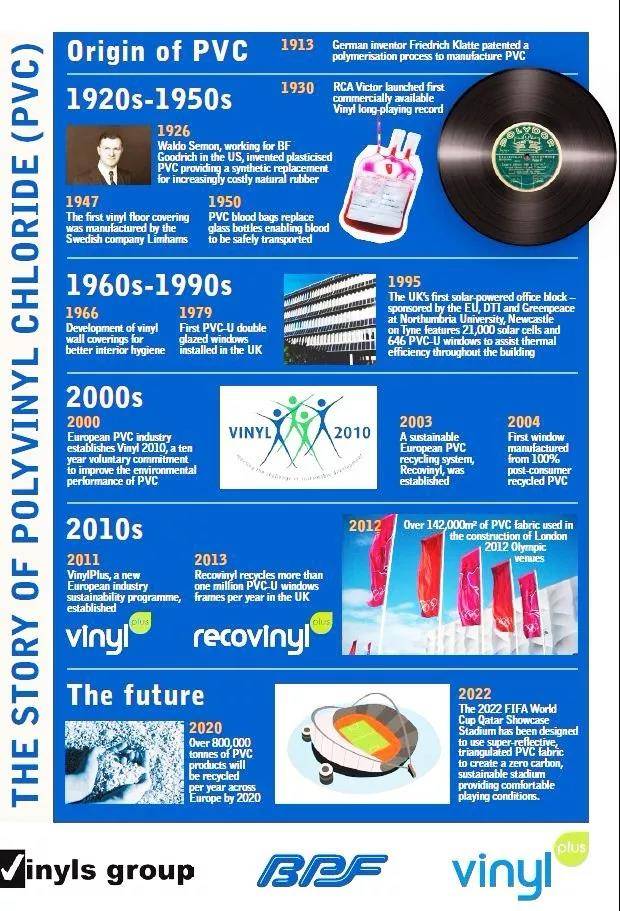

The development of polyvinyl chloride (PVC)

Polyvinyl chloride is widely used. It has been in development for more than 100 years today. Qingdao Sainuo pe wax manufacturer hascollected various dates and summarized the following content. Let us take a look at the development process of polyvinyl chloride. 1913 – German inventor Fri...Read more -

Analysis of the Causes of Air Bubbles in Road Marking Paint

The general road marking paint applied on the asphalt pavement will not cause air bubbles, but some road marking paint will appear air bubbles on the cement pavement. Today Qingdao Sainuo polyethylene wax manufacturer will show you the road marking paint causes of bubbles. 1. Some manufacturers ...Read more -

How to choose good meltblown fabrics

Meltblown non-woven fabrics are used as medical and sanitary fabrics, and are mainly used to manufacture protective clothing, surgical gowns, masks, diapers, sterilization wraps, sanitary napkins and other products. The main raw material for the production of meltblown fabrics is polypropylene ...Read more -

Exposure of Sainuo melt-blown material production formula

Since the outbreak of the COVID-19, masks and other medical protective equipment have been in short supply throughout the country. From the perspective of the mask structure, medical surgical masks generally have three layers,Both inner and outer layers are non-woven fabrics, and the middle fil...Read more -

Pigment dispersion process

The pigment dispersion process consists of three steps: wetting, dispersing, and stabilizing. During the wetting process, the air and water vapor on the surface of the pigment are replaced by the resin solution, and the dispersing agent, especially the low molecular wetting and dispersing agent...Read more -

Application characteristics of polyethylene wax in road marking paint

Polyethylene wax has a high softening point, which can improve the heat resistance of road marking paint; Low viscosity, adjustable to improve leveling; Good flow performance, conducive to construction and improve construction efficiency; High hardness, wax is distributed in the coating film to...Read more -

Causes of white spots on blown film

The reason for the white spots on the blown film is due to the fact that during the extrusion ofthe blown film, the calcium carbonate agglomerates failed to open and the dispersion was uneven. In order to disperse the calcium carbonate particles in the masterbatch uniformly into the matrix pl...Read more -

Qingdao Sainuo Class – Pressure

Most of the pressure is actually caused by ourselves, and we do n’t even know what we did. Many people are afraid or unwilling to face the real cause of his difficult situation and unhappiness. On the contrary, they will always choose the “fix the symptoms but not the cure”as a cou...Read more -

Principle of adding lubricant in PVC profile(3)

The balance of the lubrication system is not a simple balance between lubricants, but the lubrication balance of the entire formulation system. The formulations of different stable systems have different requirements on lubricants, and the lubricants played by the lubricants in the formulations...Read more -

Principle of adding lubricant in PVC profile(2)

On the premise of satisfying the needs, the lubricant should maintain the minimum dosage. Although lubricants play an important role in the formulation, it is not that the greater the amount, the better. Lubrication internal and external balance is a balance within a certain limit. ...Read more -

Principle of adding lubricant in PVC profile(1)

Pay attention to the internal and external balance of lubrication in the formula, adapt to the requirements of the lubricity of the materials in the early, middle and late stages, and achieve the consistency and long-term of the lubrication balance. polyethylene wax Lubricant (PE WAX) for PV...Read more -

Reasons for the brittleness of PVC cable materials

The brittleness of PVC cable materials is generally related to the formula components of PVC resin types, plasticizers, lubricants, fillers, etc. If the high PVC model is selected, the performance of the cable material will be brittle due to the short PVC molecular chain; ...Read more -

The role of lubricants in different PVC molding processes

The role of the lubricant is to reduce the friction between the materials and the surface of the materials and processing equipment, thereby reducing the flow resistance of the melt, reducing the viscosity of the melt, Improve the fluidity of the melt, avoid the adhesion of the melt to the equi...Read more

![[pe wax] Common testing methods for powder coatings](http://cdnus.globalso.com/sanowax/powder-coating-colours-and-finishes1.jpg)

![[Polyethylene Wax] Some limitations of color masterbatch](http://cdnus.globalso.com/sanowax/微信图片_20190917154756.jpg)